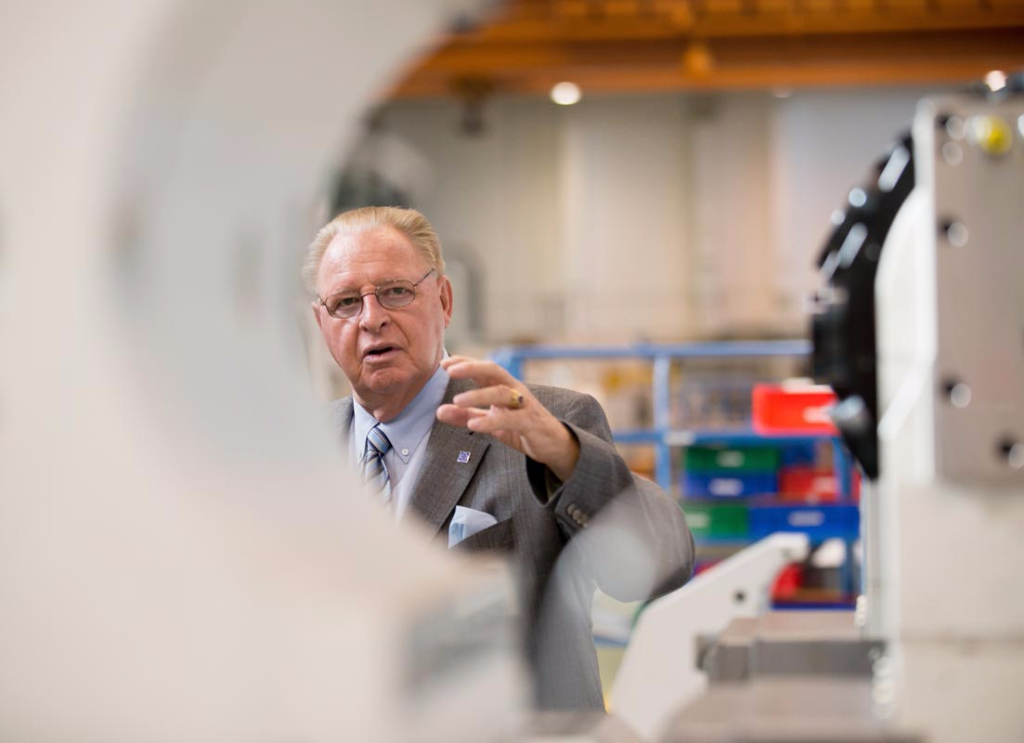

The A72 motorway in Eastern Germany goes right past the Niles-Simmons factory. The road symbolises the life of one of the region’s successful entrepreneurs – a life defined by a long journey that ultimately led back here to Chemnitz: the life of Hans J. Naumann. After the expropriation of his parents’ business in 1945 and the family’s subsequent expulsion from Saxony, 10-year-old Naumann began a journey that was to take him first to Hamburg and later to the United States, and finally back to Saxony.

The region is now home to the headquarters of the NILES-SIMMONS-HEGENSCHEIDT Group – one of Germany’s 10 largest machine tool manufacturers, which employs 1,360 people worldwide, 450 of them in Chemnitz.

Entrepreneurial spirit and a long-term view

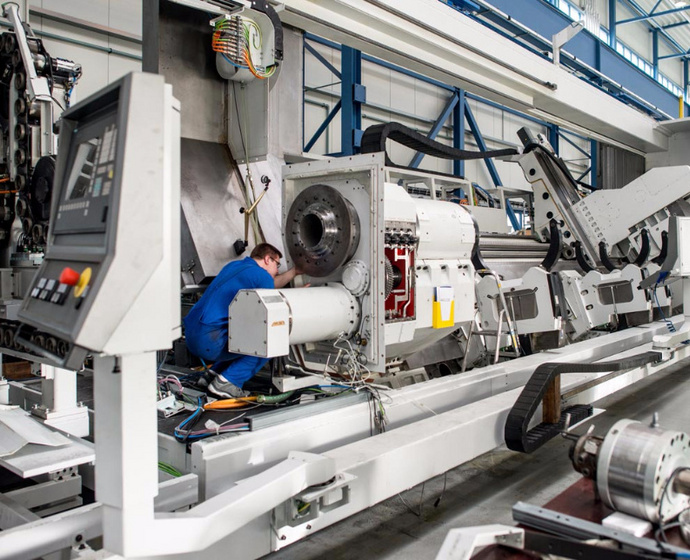

As a global leader in machine tools for the production of railway wheels, axles and wheelsets and equipment for maintaining wheelsets for all types of rail vehicles, the Group occupies an exclusive niche in the market. The highest levels of quality and precision are demanded down to the very last micrometre, given the huge importance of safety and reliability in the transport sector. In the early 1990s, though, it looked far from certain that the Chemnitz production facility of this former GDR state enterprise would one day have a part to play in the company’s success story. “When the Treuhand agency put the firm up for sale in 1991, I applied immediately,” recalls the company owner. “A key element of the acquisition was a major Russian contract for lathes that was worth around 36 million marks, equivalent to a year’s output. I wanted to fulfil the contract and bring the technology and the quality of the lathes up to Western standards at the same time.” But the Russian customer ran out of money in 1992 and the company suddenly found itself in a critical situation. “NILES was paying out a million marks a month in wages and salaries, but had no products suitable for the Western market,” says Naumann. “It was incredibly difficult to sell machines built for Russia in the West.” A solution was found thanks to the expertise of SIMMONS Machine Tool Corporation, which Naumann had acquired in 1982. Wheelset machining systems were successfully incorporated into the product range alongside the lathe products made in Chemnitz. A major contract from General Motors in the mid-1990s signalled the start of the Saxon phase of the company’s success story. NILES-SIMMONS supplied over 100 machines for machining crankshafts to five new GM plants in the US.

Quality in demand around the world

In 1982, Naumann purchased SIMMONS along with the engineering division of US firm NILES. The Group continued to expand with the acquisition of Erkelenz-based manufacturer HEGENSCHEIDT in 2001, which Naumann had managed after his return to Europe in 1970. “I wanted to position the Group as broadly as possible in the market to avoid becoming too dependent on one industry,” explains the entrepreneur. It was a clever strategy, as the Group now supplies huge metal machining centres to companies across a wide range of industries, including aircraft and aerospace, automotive and trucks, general engineering, the tool and die industry, and the railway and metro sector. NILES machines on all continents produce intricate turbine shafts, crankshafts weighing several tonnes for ship diesel engines, and wheelsets for high-speed trains. In other words, Saxon precision keeps the world moving.

pictures: (c) Martin Förster www.foerstermartin.de